TPM

What is Total Productive Maintenance (TPM)?

It can be considered as the medical science of machines. Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same time, increasing employee morale and job satisfaction.

TPM brings maintenance into focus as a necessary and vitally important part of the business. It is no longer regarded as a non-profit activity. Down time for maintenance is scheduled as a part of the manufacturing day and, in some cases, as an integral part of the manufacturing process. The goal is to hold emergency and unscheduled maintenance to a minimum.

Total productive maintenance is a complete system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents.

One distinct advantage of total productive maintenance is that it empowers the shop floor to work in a concerted manner to ensure that machines are functioning at their optimal performance.

In fact, in a lean production setup that is practicing TPM, you find it difficult to distinguish between normal operators and maintenance staff.

This is because they all are proactively involved in the maintenance of machines which leads to increased productivity, lower costs, improve quality and extended machine lifespan.

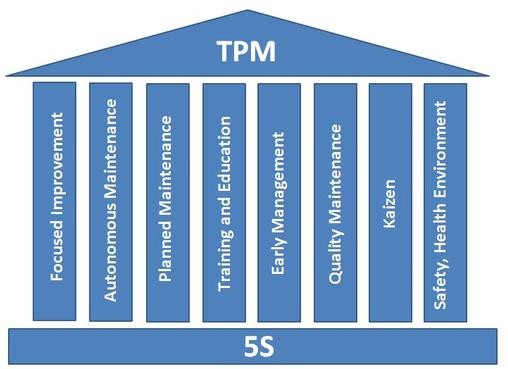

The Eight Pillars

Once a high degree of stability is established using the 5S program, an organization can start implementing the total productive maintenance in earnest.

Total productive maintenance has eight pillars that are aimed at proactively establishing reliability of machines.

One point that has to be made here is that people are centre of this system and must be continuously trained to identify and eliminate waste.

It is a system that is based on a clear set of principles and structures and should not be interpreted to be a set of tools or techniques to be applied haphazardly.

TPM Pillar 1: Autonomous Maintenance (Jishu Hozen)

Jishu Hozen or Autonomous Maintenance places the responsibility of basic maintenance activities on the hands of the operators and leaves the maintenance staff with more time to attend to more complex maintenance tasks.

Maintenance activities that are carried out by shop floor workers include basic cleaning of machines, lubricating, oiling, and tightening of nuts and bolts, inspection, diagnosis of potential problems and other actions that increase the productive life of machines or equipment.

By carrying out these maintenance activities, the workers become more responsible towards their work and downtime is reduced because there is no need of waiting for maintenance staff as they can correct simple problems that may occur from time to time.

Maintenance staff on the other hand will be more concerned with issues that require a higher technical ability such as replacement and servicing of internal parts. They will also carry out scheduled or planned maintenance which means production will not be interrupted unnecessarily.

Autonomous maintenance has benefits to both the workers and the organization as a whole:

- Operators become more responsible and concerned about the condition of equipment they use on a daily basis

- Skill levels of workers increase as they gain an understanding of the general working of equipment thus achieving the multi-skilling objective of a lean organization

- Machines operate at their optimal level because basic maintenance such as cleaning and lubrication is carried out more regularly

- Problems are identified and corrected before they go out of control leading to major breakdown of equipment.

- Engineering staff are freed-up to carry out higher-level maintenance activities on sensitive and critical equipment thus reducing the overall system downtime

By carrying out the simple activities in this TPM pillar, capital investments are drastically reduced because the organization has reliable equipment and does not have to replace machines as often. This is because the lifespan of machines is drastically increased as forced deterioration is checked through constant monitoring and maintenance.

TPM Pillar 2: Planned Maintenance

Planned maintenance is the scheduling of maintenance activities based on observed behaviour of machines such as failure rates and breakdowns. By scheduling these activities around such metrics, the cycle of breakdowns and failure is broken thus contributing to a longer service life of machines. Because there is a specific time for maintaining equipment, production is rarely interrupted as these activities are scheduled around the time when they are idle or are producing very little. In fact, production functions can build up some inventory to allow for the planned maintenance to be carried out as they have prior information of when these activities are scheduled. This is in contrast to reactive maintenance that waits for problems to occur which has a negative impact on productivity due to machine downtime. Production will never be sure when they will be able to get back to work because the problems are not clear and technicians will just be doing exploratory work to find causes. There are many obvious benefits of taking the planned maintenance approach as compared to being reactive when technical issues arise:

- By constantly scheduling maintenance activities, the number of breakdowns gradually decrease and this then increases the capacity for productive activities

- Production functions can continue with their activities uninterrupted because they know exactly when maintenance will take place.

- Maintenance is done when the production floor is not very busy

- Capital investments in machinery are reduced as the equipment is utilized to its fullest potential

- Expensive machine parts do not have to be kept in inventory as there is better control of the various categories of parts.

Pillar 3: Quality Maintenance

This TPM pillar addresses the issue of quality by ensuring equipment is able to detect and prevent errors during production. By detecting errors, processes become reliable enough to produce the right specification the first time. The quality aspect of maintenance is very important because it helps in preventing defects from moving down the value chain which only leads to a lot of rework. Using lean tools such autonomation (jidoka) and andon, machines detect and report any abnormal conditions, thereby releasing the operators from the tedious monitoring that is common in non-lean operations. The quality maintenance pillar of TPM also ingrains in the workforce the habit of finding the root cause of problems instead of rushing to solutions that are not permanent. This is done through tools such as 5 Whys root-cause-analysis and Ishakawa diagrams which are structured ways of getting to the real reasons why problems occur. Quality maintenance offers a number of advantages including:

- Targeted improvement activities address quality issues that arise from time to time in the workplace by coming up with permanent countermeasures

- Defects are minimized or completely eliminated

- Cost of poor quality is reduced by getting quality right the first time. This happens because errors are caught before they move down the value stream which reduces the amount of rework that has to be done to correct them

Pillar 4: Focused Improvement (Kobetsu Kaizen)

In this pillar, cross-functional teams are assembled with the main working on problematic equipment and coming up with improvement suggestions.

The use of cross-functional teams is important so as to have a large and varied number of employees involved so as to bring in different experience as well as viewpoints to the table.

These teams are better placed to come up with solutions to the issues that arise concerning crucial machines. The kaizen projects for maintenance also serve as training sessions on the total productive maintenance tool which results in the organization having a large pool of skilled personnel.

Once a focused improvement team for maintenance has been identified and trained, they choose at least one piece of equipment as a pilot for their activities. Problems relating to the equipment are identified and improvement goals set in a three to five day in-house kaizen event.

During the events, the participants map the current state of affairs as a baseline performance measure on which they will compare any future performance after improvement.

The teams work together to make sure that any solutions that they come up with are implemented and any follow-up activities are completed within the agreed timelines.

The focused improvement pillar of TPM is therefore advantageous as quick gains are made which helps in promoting the lean methodology to workers who may not have bought in to the program.

The organization is able to build-up a large base of employees that are conversant with the right tools for solving problems and getting to the root cause.

Pillar 5: Early Equipment Maintenance)

The fifth TPM pillar of Early Management uses the experience gathered from previous maintenance improvement activities to ensure that new machinery reaches its optimal performance much early than usual.

Working with a myriad of stake-holders including suppliers, the company is able to hit the ground running with highly reliable and productive equipment.

Such an approach has a positive impact on profitability of the company as maintenance costs are dramatically reduced.

The productivity as well as output quality of the machines is also guaranteed from the very first day when the equipment is commissioned.

Using the input from the people who use these machines on a daily basis, suppliers of the equipment can improve the maintainability and operability in the next iteration of their products.

Among the factors that should be considered when designing new equipment include:

- Ease of cleaning and inspection

- Ease of lubrication

- Accessibility of equipment parts

- Improving operability of machines through ergonomically placing controls in such a way that they are comfortable to use by operators

- Making it easier for changeover to take place through simplification of procedures or eliminating the unnecessary ones

- Feedback mechanisms that prevent out-of-spec situations as well as clear indications of the correct specifications for quality products

- Increased safety features

Though the machines may be designed and manufactured with all the above considerations in mind, it is still possible that there will be bugs that will need to be removed before full commissioning. Early management is a system that addresses these concerns and uses input from the staff who will be using the equipment before installation.

Pillar 6: Education and Training

This pillar is concerned with filling the knowledge gap that exists in an organization when it comes to total productive maintenance.

Lack of knowledge in the tools can stand in the way of proper implementation leading to mediocre results at best and failure at worst.

Without proper training, tools such as TPM can be misunderstood by the staff which can result in disastrous results for the company.

Ensuring that employees are trained gives the organization a reliable pool of knowledgeable staff that can drive the initiative competently.

TPM education and training pillar is a company-wide initiative that does not leave out any employee cadre. In fact, all levels in the organization – from the operators to senior managers – get involved in the TPM training as well projects.

Through training, operators’ skills levels are raised to the point where they are able to carry-out basic maintenance activities that were previously the preserve of maintenance staff.

The technical staff are then taught higher level skills such as preventive maintenance and analytical skills to help become more proactive to problem solving.

At the managerial level, managers also learn the TPM skills so as to become competent mentors to their juniors as well as be involved in coaching programs.

Pillar 7: Health, Safety & Environment

That workers must be able to perform their functions in a safe environment devoid of health risks cannot be gainsaid.

The health, safety and environment pillar of total productive maintenance ensures that all workers are provided with an environment that is safe and that all conditions that are harmful to their well-being are eliminated.

While the goal of any organization is to produce value for the customer in an efficient and productive manner, this should be done in a way that is does not put to risk the safety of workers. It is therefore important that any solutions which are put in place should consider the well-being of the worker above all else. This is because injuries or fatalities reduce when there is a concerted effort to make the workplace an accident-free environment.

The cross-functional teams will work towards making machines safe to use by the operators by putting in place such features as guards, works standards, use of personal protective equipment and first-aid kits in the work-area. Each of these measures are aimed at improving the safety of the machines so as to have a more productive work-force.

Pillar 8: TPM in Office Functions

Taking TPM to the administrative functions is the next logical step in the total productive maintenance program so as to have the whole organization speaking from the same page.

As these are supportive functions, making them understand and apply the principles of lean in their own operations makes it easy for them to provide efficient service to the main value-creating processes.

In addition, spreading the initiative into other functions removes the silo mentality and encourages horizontal cooperation within the workforce. The organization will also benefit by having a larger pool of workers who understand the principles of TPM and can easily be called upon to play a positive role in its implementation.

The TPM principles can also be applied as stand-alone techniques to improve the efficiency of these supportive functions. For example, if the administrative functions are able to improve their order processing procedures, then material will get to the shop-floor in a flawless manner which will have a positive effect on the workflow.

If suppliers are paid on time, they will have the ability to provide the services that they have been contracted to give without any problem.

As we conclude with this pillar, it is important to note that each has its role in the greater scheme of things and should be employed at the appropriate time.

While each TPM pillar has can be applied as a stand-alone component, the aim should be to sequentially implement each of the pillars so as to have get the full benefits of a complete system.

Get in Touch! Ask us any question/query on +91-9867-180-395. We would be happy to answer your concerns. You can also drop an email at info@ascentinspecta.com